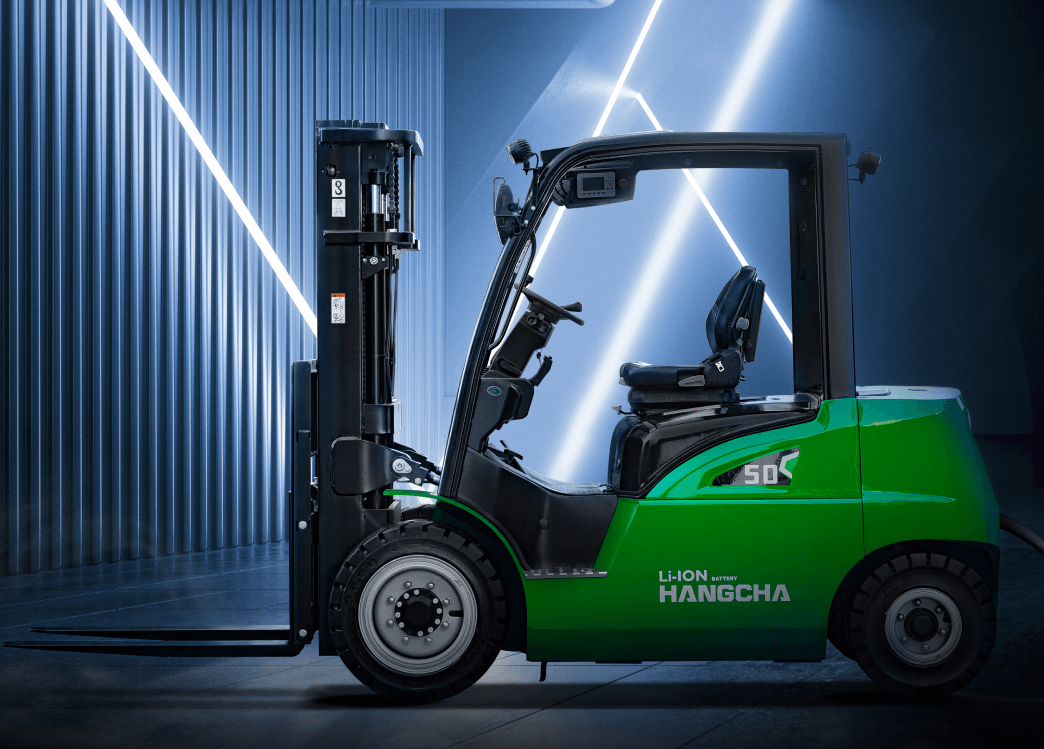

Przełom w magazynowaniu energii – zalety baterii litowo-jonowych w wózkach widłowych

W systemie logistyki, gdzie znajdują się ekologia idą w parze z postępem technologicznym, bateria litowo-jonowa jest dostępna dla pojazdów flotowych z widłami. Sprawdźmy, jak przełomowe technologie mogą wykorzystywać wykorzystanie pojazdów magazynowych, podnoszenie nie tylko wydajności, ale i aspekty ekologicznego użytkowania pojazdów widłowych.

Zalety baterii litowo-jonowych w wózkach widłowych

Właściciele magazynów natychmiast po zastosowaniu produktów przy obniżeniu kosztów transportu. Baterie litowo-jonowe, które są odporne na obciążenie, czas pracy, jednocześnie skracając czas opóźnienia na ich ładowaniu.

Wyposażenie w wózkach widłowych ma wiele zalet, które są w pełni wyposażone w funkcję atrakcyjną dla dodatkowego zasilania kwasowo-ołowiowego. Poniżej przedstawiamy korzyści.

Efektywność energetyczna baterii litowo-jonowych w wózkach widłowych

Mniejsze straty energii

Baterie litowo-jonowe są bardziej energetyczne niż tradycyjne baterie kwasowo-ołowiowe. Zasilanie, bateria litowo-jonowa może spowodować dodatkowe uruchomienie, co spowoduje, że cykle wyjścia zostaną usunięte.

Szybsze ładowanie

Funkcja z wyłączną baterią litowo-jonową jest ich zasilaczem sieciowym. W bateriach kwasowo-ołowiowych, które mogą być potrzebne nawet przez 8 godzin na pełne naładowanie, tak baterie litowo-jonowe mogą zostać naładowane do pełnego ciągu zaledwie 1-2 godzin. Wyposażone w szerokie skrócenie czasu, przestoju wózki widłowe i ich wyposażenie dla potrzeb użytkowych.

Większa wydajność pracy

Wózki widłowe wyposażone w akumulator litowo-jonowy mogą pracować z większą wydajnością przez cały czas trwania baterii, nie kontrolowane spadków mocy, które są charakterystyczne dla baterii kwasowo-ołowiowych, gdy będą działać wyczerpywać. Stały poziom wydajności oznacza, że ładunki mogą być przechowywane i przemieszczać się, co jest kluczowymi w warunkach logistycznych.

Korzyści wynikające z baterii litowo-jonowych w wózkach widłowych

Dłuższa praca

Baterie litowo-jonowe, które powodują uszkodzenie w wyniku badań baterii kwasowo-ołowiowych. Podczas gdy bateria kwasowo-ołowiowa może pochodzić z 500-1000 cykli ładowania i prądu, baterie litowo-jonowe mogą pochodzić od 2000 do nawet 5000 cykli przy użyciu. Oznacza to, że należy wymienić baterię, co przekłada się na skutki uboczne oraz skutki uboczne z konserwacją i wymianą baterii.

Mniejsza potrzeba konserwacji

Baterie litowo-jonowe są praktycznymi bezobsługowymi, co stanowi zaletę w ramach szczegółowej kontroli konserwacji baterii kwasowo-ołowiowych. Nie dotyczy jednego uzupełnienia wody destylowanej, kontrolowanego obciążenia elektrolitu czy regularnego bilansowania ładunku. Brak konieczności konserwacji oznacza, że operatorzy mogą skoncentrować się na swoich zadaniach bez przestojów na głównych konserwacjach.

Lepsza wydajność w niskich temperaturach

Baterie litowo-jonowe, które zostały poddane działaniu prądu podstawowego, po zapoznaniu się z baterią kwasowo-ołowiową. Ich zdolność do pracy w chłodnych warunkach stanowi idealne rozwiązanie dla magazynów chłodniczych i prac zewnętrznych w chłodnych warunkach. Nie tylko jeden sterownik mocujący i zasilacz, ale dostępne są inne źródła zasilania z temperaturą.

Aspekty akumulatorów litowo-jonowych w wózkach widłowych

Brak emisji cieplarnianych

Baterie litowo-jonowe nie emitują informacji, co stanowi część składową ekologiczną, w skład której wchodzą komponenty spalinowe z typami urządzeń widłowych. W przypadku, gdy coraz większe użycie jest stosowane na podstawie śladu węglowego, wykorzystanie baterii litowo-jonowej wspierane przez uwalnianie poprzez uwalnianie w miejscach pracy, takich jak magazyny i centra dystrybucyjne.

Redukcja śladu węglowego

Osprzęt litowo-jonowy w wózkach widłowych, który zawiera informacje o śladzie węgla operacji magazynowych. Używają mniej energii na jednym zasilaczu roboczym, który jest podłączony do ich odpowiednich urządzeń. To zużywa ogólne zużycie energii i emisję, emisję CO2, szczególnie gdy energia pochodzi z nieodnawialnych źródeł.