Gray autumn? Not necessarily!

Choose your own forklift color to brighten up your company

or customize the equipment to meet the specific needs of your business.

We present an example of color change in the HANGCHA XF series LPG-powered forklift.

In today’s dynamic business environment, where speed and logistics efficiency determine competitive advantage, small and medium-sized enterprises face the challenge of ensuring operational efficiency without straining their budgets. One solution that can significantly enhance efficiency is the use of forklifts. Discover how proper utilization of forklifts can contribute to increasing your company’s productivity.

Forklifts are not just equipment for large warehouses or logistics centers. Small and medium-sized enterprises across various industries can also benefit from their use. Here are some key reasons:

Forklifts significantly accelerate the loading and unloading processes, which is particularly important for small and medium-sized enterprises, where every time-saving measure translates to increased efficiency. Manually moving heavy loads not only takes more time but also carries the risk of errors and damage to goods.

With forklifts, businesses can better utilize their available storage space by employing high racks and stacking goods vertically. This allows for increased storage capacity without the need to invest in additional space, which is crucial for smaller enterprises often operating in limited areas.

Proper use of forklifts in accordance with health and safety regulations reduces the risk of accidents and injuries in the workplace. Forklifts are designed to safely transport heavy and unwieldy loads, which lessens the physical burden on employees and protects their health. For more information on workplace safety with forklifts, check our previous post, available HERE.

The variety of forklift models available on the market means that every business can find a solution tailored to its specific needs. Whether a heavy-duty forklift for transporting heavy materials is needed or a compact model for tight spaces, companies can configure their fleet of forklifts to best support their operations.

In some industries, such as construction, manufacturing, or processing, forklifts can be used for specialized tasks, such as lifting and transporting hazardous materials or handling loads with unusual dimensions. Customizing a forklift to specific needs enables the efficient and safe execution of even the most complex tasks.

Choosing the right forklift depends on several factors. Here’s what to consider:

The first step in selecting a forklift is a thorough assessment of the business’s operational needs. Consider what tasks the forklift will perform, what loads it will transport, and how often it will be used. Will it operate mainly indoors or outdoors? What is the maximum weight and size of the loads it will handle? Answers to these questions will help determine the type and specifications of the forklift that best meets the company’s expectations.

Forklifts come with various power sources: electric, gas, diesel, or LPG. Each has its advantages and limitations. Electric forklifts are quiet, eco-friendly, and ideal for indoor work but may require frequent recharging. Internal combustion engine forklifts offer more power and are better suited for outdoor operations but produce emissions and can be louder.

The space where the forklift will operate is crucial when selecting a model. For tight warehouses with limited maneuvering space, electric forklifts, which are typically smaller and more maneuverable, may be ideal. For outdoor operations where space constraints are not an issue, larger internal combustion engine forklifts may be more appropriate. If you want to learn more, HERE you can find a comparison of internal combustion and electric forklifts.

The budget is a key factor in choosing a forklift. In addition to the purchase price, consider operating costs such as fuel, maintenance, and potential repairs. Electric forklifts may have a higher initial cost but often have lower operating costs and are more environmentally friendly compared to gas models.

If possible, test the selected forklift models before making a purchase. Many companies offer rental or demonstration options, allowing for an evaluation of how a particular model performs in the company’s real operational conditions. This is an important step that can help avoid future disappointments and ensure that the investment fully meets business needs.

Safety and work ergonomics are extremely important when choosing a forklift. Look for models equipped with advanced safety systems, such as obstacle sensors, stability control systems, and LED lighting to improve visibility. Additionally, the ergonomics of the operator’s workspace, including seat adjustment, control layout, and visibility, are crucial for ensuring work comfort and minimizing the risk of injury and fatigue during prolonged use.

Before purchasing a forklift, pay attention to the availability of technical service and spare parts. Choosing equipment from a reputable manufacturer or supplier with a well-developed service network ensures ease in maintaining the forklift in good technical condition. This, in turn, will lead to lower operating costs and extend the investment’s lifespan.

Remember that purchasing a forklift is a long-term investment. When selecting a model that best meets the current needs of the business, it’s also worth considering future growth and potential changes that may occur in operations. Flexibility, the ability to expand, and adaptability to changing work conditions are essential factors to take into account.

Before making a decision, it’s advisable to consult suppliers or experts in the field of forklifts. They can offer valuable insights regarding the latest technologies, models, and best practices for maintaining and operating forklifts. Such consultations can also help in finding forklifts that best fit the specific needs of the business.

Do you want to optimize the work in your warehouse or construction site to make it more efficient and safer? Customizing a forklift tailored to the unique requirements of your operation could be the key. In this article, we will explore how appropriate forklift customization can transform challenges into opportunities.

Tailoring a forklift to specific operational needs and working conditions can significantly impact efficiency, safety, and overall operational effectiveness. Understanding why forklift customization is essential allows for better utilization of their potential. Below, we outline several key benefits resulting from appropriate forklift customization:

Customizing forklifts allows for precise adaptation to specific tasks. For instance, forklifts with modifications such as increased lifting capacity, specialized attachments, or improved maneuverability can significantly enhance logistics processes, especially in demanding industries like construction, lumber, or warehousing. This enables employees to perform tasks more quickly and effectively.

Safety is a priority in any work environment, particularly where heavy equipment is used. Customizing forklifts, such as adding enhanced lighting systems, rearview mirrors, or safety sensors, can significantly reduce the risk of accidents and injuries. Adapting forklifts to specific working conditions, such as limited spaces or outdoor work, also contributes to increased safety.

Customizing forklifts for specific applications can lead to longer service life and reduced maintenance needs. Adapting a forklift to specific working conditions, such as extreme temperatures or specific load types, ensures that the equipment is more resistant to damage and wear, ultimately resulting in cost savings.

Work ergonomics is another key aspect of customization. Adjusting the forklift’s cabin, such as with adjustable seats, appropriate positioning of control panels, or climate control systems, can enhance operator comfort and efficiency. Better working conditions translate to less fatigue and greater concentration, which is crucial for safety and productivity.

Forklift customization opens up a wide range of possibilities, allowing for equipment adaptation to nearly any work environment and task. Below, we highlight the main aspects that can be tailored to meet specific requirements.

Tires are a critical element that can be customized to improve performance and safety when operating a forklift. The choice of appropriate tires depends on the type of surface the forklift will be navigating:

Increasing the lifting capacity of a forklift is crucial in areas where heavy loads are regularly transported. Various modification options exist, from reinforcing the frame to employing stronger lifting mechanisms, enabling safe and efficient handling of larger weights.

Customizing the forklift’s cabin to meet operator needs is essential for ensuring comfort and work efficiency. Customization possibilities include:

Implementing modern technologies into forklifts significantly enhances their functionality. These solutions include:

Although it may seem that the forklift’s color is merely an aesthetic choice, it serves more critical functions, especially concerning safety, identification, and compliance with corporate requirements. Changing the color of a forklift as part of customization is a practice increasingly adopted across various industries. Bright colors, such as yellow, orange, or red, enhance the visibility of forklifts, which is crucial for safety in crowded or poorly lit work environments. Companies also often use colors aligned with their branding to reflect their identity and facilitate fleet management. Customizing the color can also positively impact employee morale, fostering a stronger sense of team belonging.

Forklift customization is often associated with selecting the appropriate attachments that allow the machine to be tailored for specific tasks and working conditions. Choosing the right attachments not only enhances the forklift’s versatility and efficiency but can also significantly impact safety and comfort at work. Below, we present various types of attachments available on the market and how they can support diverse operational needs.

Standard forks can be replaced with specialized ones tailored for specific types of loads, such as:

Many types of attachable devices enhance the forklift’s functionality, including:

In some cases, customization may include advanced systems for load handling:

Customization may also involve additional features that enhance workplace safety and comfort, such as:

For more information on forklift attachments, please refer to our previous article.

Choosing the appropriate forklift customization is crucial to ensure that the investment in such changes yields the expected benefits. This process requires thoughtful analysis, consultations with experts, and assessment of potential benefits relative to costs. Below, we outline steps to help make the right choice.

The first step is a thorough analysis of business needs and the specifics of the work environment. Key aspects to consider include:

After identifying needs, it’s advisable to consult with experts specializing in forklifts. Professionals can advise on available customization options, help evaluate the pros and cons of various solutions, and indicate potential costs. Technical expertise is essential for choosing the most efficient and economical solutions.

The next step is to evaluate the costs and benefits associated with different customization options. It is important to consider not only the initial cost but also the long-term savings resulting from increased efficiency, reduced downtime, and lower maintenance costs. This analysis should include:

If possible, it is worthwhile to request demonstrations or tests of forklifts with applied changes. This will help better understand how specific modifications impact work and whether they meet expectations.

default

default

default

default

We are delighted to invite you to INTRALOGISTICA 2024 – the International Trade Fair for Warehouse Logistics, which will take place from January 24 to 26 in Nadarzyn.

INTRALOGISTICA 2024 is a meeting place for professionals in the warehouse logistics industry, providing an opportunity to exchange experiences and establish valuable new contacts. We believe that our booth will inspire you and serve as a source of knowledge, allowing you to view warehouse logistics from a fresh perspective.

Our team will be available to you at booth D2.05. We are eager to share our expertise, experiences, and answer any questions you may have, helping you find solutions perfectly tailored to your business needs.

We warmly invite everyone interested in innovations in warehouse logistics, both professionals and newcomers to the industry. Join us to discover how modern solutions can contribute to the development and growth of your business.

We look forward to seeing you in Nadarzyn – you won’t want to miss it!

Garden enthusiasts! Are you ready for the most important event in the fruit and vegetable industry this year? The Fruit and Vegetable Trade Fair will take place on January 17-18, 2024, in Kielce, and we, Toolmex Truck, are proud to be a part of this fantastic event!

This is a unique opportunity to discover the latest trends, explore innovative technologies, and establish valuable business contacts. We warmly invite you to visit our booth (BOOTH F1), where we will showcase our latest offerings and solutions. Our team will be available to provide professional advice and answer any questions you may have.

Get ready for two days full of inspiration, learning, and amazing experiences. Whether you are an experienced fruit grower or a budding enthusiast, you will definitely find something for yourself at the Fruit and Vegetable Trade Fair in Kielce. Join us and thousands of others at the fair in Kielce. We look forward to seeing you!

Visit our

VIRTUAL 3D BOOTH

from the Central Agricultural Fair in Nadarzyn (11.2021)

and take a closer look at our popular models:

https://my.matterport.com/show/?m=FEdhh7HqozU

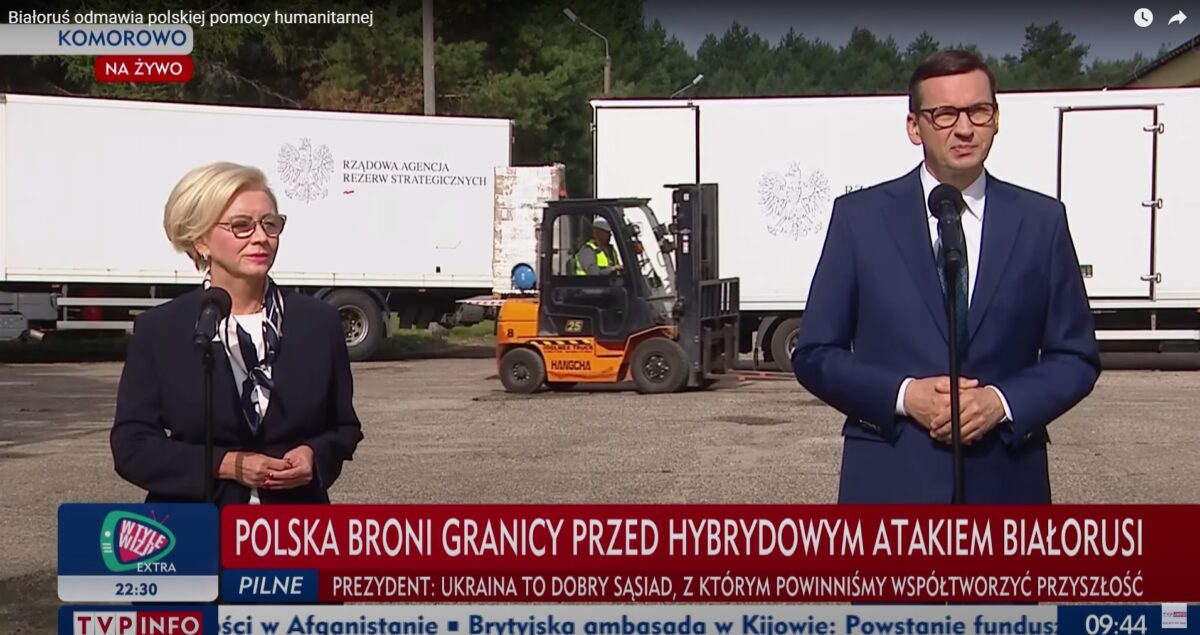

Recently, you may have seen our forklifts in various media outlets (TVP, TVN, POLSAT, etc.).

The cameras have truly fallen in love with our equipment.

This is due to the fact that in this era of the most significant global crisis in years, one simply cannot take risks.

To unload goods during uninterrupted, 24-hour operations, the best and most reliable equipment is required.

Therefore, the choice of TOOLMEX TRUCK forklifts for the strategic activities of our country,

such as supporting the Material Reserves Agency, seems obvious.

Our forklifts were once again in action during the LIVE broadcast of Prime Minister Mateusz Morawiecki’s press conference.

The entire material is available, for example, at this link:

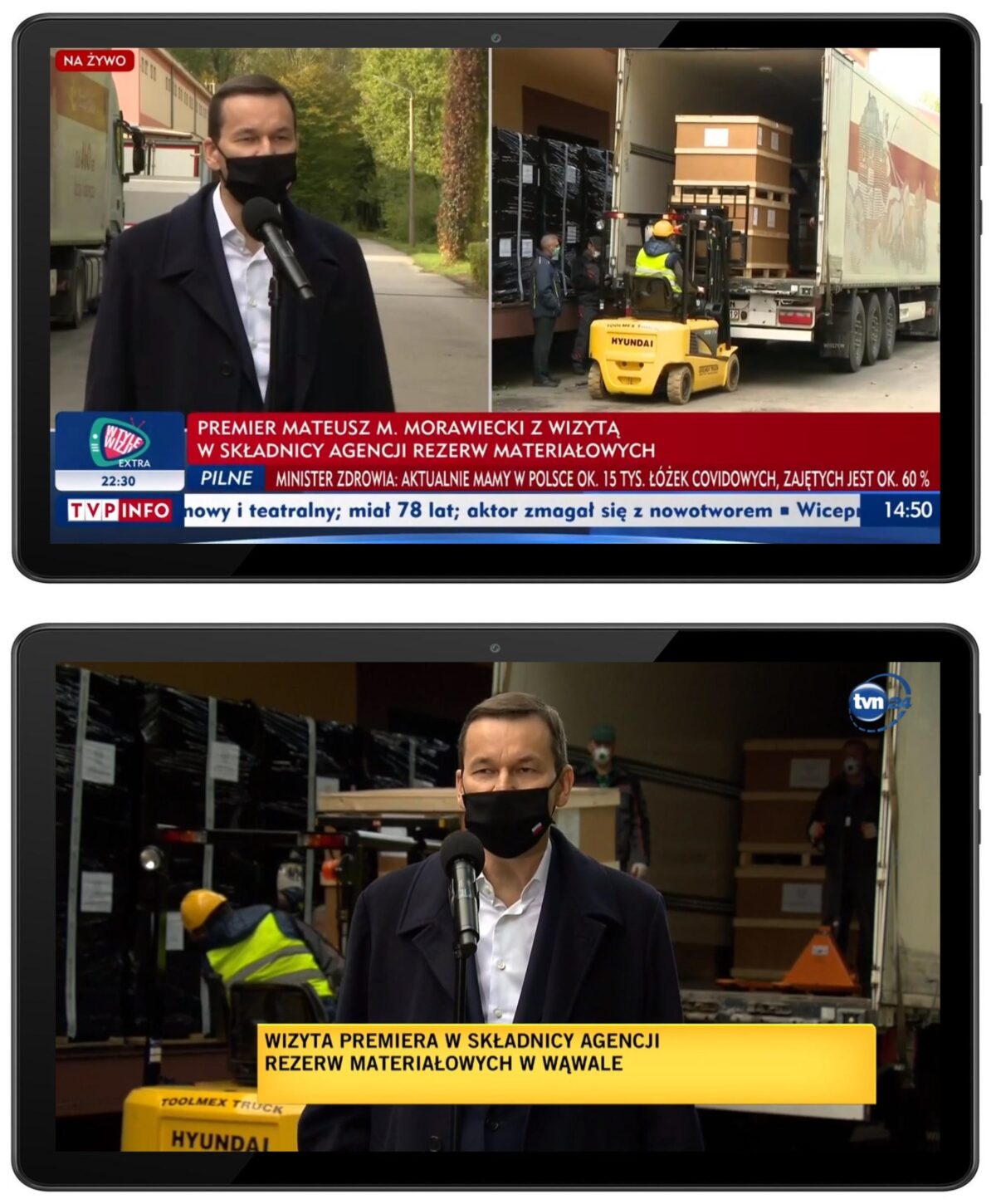

Recently, you may have seen our forklifts in various media outlets (TVP, TVN, POLSAT, etc.).

Cameras have truly taken a liking to our equipment.

This is due to the fact that in the era of the greatest global crisis in years, one simply cannot afford to take risks.

For unloading goods in continuous, 24-hour operations, the best and most reliable equipment is necessary.

Thus, the choice of TOOLMEX TRUCK forklifts for the strategic activities of our country,

such as supporting the Material Reserves Agency, seems obvious.

Our forklifts were once again in action during THE LIVE press conference of Prime Minister Mateusz Morawiecki.

The entire footage is available at the following link:

https://www.youtube.com/watch?v=ccEbK645yR4