Discover one of the most revolutionary inventions in the history of logistics and warehousing—the forklift. This indispensable tool has become an integral part of today’s industrial and commercial landscape. Learn the history of forklifts to understand how they have evolved to meet the growing demands of the market.

The History of Forklifts: Early Development Years

The origins of forklifts trace back to the early 20th century, a period of rapid industrial growth that revolutionized production and logistics. At the time, the need for more efficient material handling was more pressing than ever. The first devices, which can be considered predecessors of today’s forklifts, emerged as a response to these challenges.

Tructractor: The Beginning of an Era

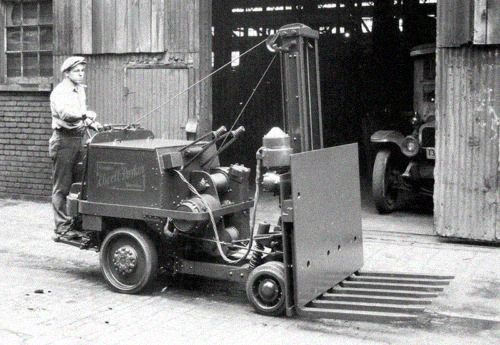

1917: The Clark Equipment Company, a pioneer in industrial equipment, developed the “Tructractor.” Initially, it was a simple towing vehicle used internally to transport materials within Clark’s factory. Its effectiveness quickly attracted the attention of other businesses, leading to the start of commercial production. The Tructractor is considered the first step toward the forklifts we know today.

Growth and Innovation

1920s: Growing interest in mechanized material transport led to the development of equipment with lifting capabilities. Yale & Towne Manufacturing, now known as one of the leading forklift brands, introduced the first models with manual lifting functions. This innovative approach paved the way for further research and advancements in material handling mechanization.

Technological Breakthroughs and Adaptation

Late 1920s to Early 1930s: Advancements in power systems and hydraulic technology enabled the creation of more advanced forklifts. These machines gained the ability to lift heavier loads to greater heights, significantly increasing their utility in industrial and warehouse environments. The first true forklifts began to appear, equipped with either electric or combustion engines, marking substantial progress over their earlier prototypes.

Innovations and Technological Breakthroughs That Shaped Modern Forklifts

From the 1930s to the end of World War II, forklifts underwent intense technological development. This period was marked by dynamic changes, adaptation to new conditions, and groundbreaking innovations that permanently reshaped the industrial landscape.

World War II

1939-1945: World War II had a significant impact on accelerating forklift development. The logistical demands during the war, including the rapid movement and storage of supplies, required more efficient and versatile equipment. During this time, forklifts became widely used in military warehouses and ports, further driving their refinement and popularity.

Advancements in Power and Lifting

1950s and 1960s: After the war, with the rebuilding and economic growth, another wave of innovations occurred. The introduction of electric forklifts and the improvement of hydraulic lifting systems significantly enhanced their operational efficiency. Electric drives offered quieter operation and less pollution, making them ideal for enclosed spaces like warehouses and production halls.

Safety and Ergonomics in Focus

1970s: Growing awareness of safety and ergonomic issues led to new standards and regulations. Forklifts began to feature improved operator protection systems, such as cabins that shield against falling objects. Enhancements in operator ergonomics, including better seating, controls, and visibility, helped boost both productivity and workplace safety.

The Evolution Toward Automation and Smart Systems

Late 20th to Early 21st Century: The latest era of forklift development has focused on automation and integration with advanced Warehouse Management Systems (WMS). Forklifts have become more technologically advanced, featuring capabilities such as automated navigation systems, remote control, and the ability to work within high-density storage systems. These advancements not only increased efficiency but also paved the way for fully autonomous warehouse operations.

The Modern Era: Forklift Revolution in the Age of Technology and Automation

As industry and technology entered the new millennium, forklifts underwent yet another evolution, reflecting advancements in automation, digitization, and sustainability. The modern era of forklifts is characterized not only by technical improvements but also by integration with advanced warehouse management systems and a focus on sustainable development. Here are some key aspects of this revolution:

Integration with Information Technologies

- Advanced Management Systems: Modern forklifts are often equipped with software and sensors that allow integration with WMS, enabling the automation of processes such as inventory management, load tracking, and route optimization within warehouses.

- RFID and QR Code Technology: These technologies enable easy identification of goods and automatic recording of load movements, significantly streamlining logistics processes.

Automation and Robotics

- Autonomous Forklifts: The development of autonomous vehicle technology has reached forklifts, allowing them to operate independently without direct human involvement. These solutions increase safety, efficiency, and productivity in warehouses.

- Vision Systems and Navigation: Modern forklifts are equipped with cameras and navigation systems that assist in precise maneuvering and enable operations in more complex warehouse environments.

Sustainable Development and Ecology

- Electric Forklifts: Transitioning from fuel-powered forklifts to electric models significantly reduces CO2 emissions and noise, aligning with global sustainability trends.

- Renewable Energy and Batteries: Investments in technologies such as lithium-ion batteries or hydrogen as a power source for forklifts open new perspectives for eco-friendly and efficient operation.

Personalization and Ergonomics

- User Adaptation: Modern forklifts offer extensive customization options and adaptability to meet operators’ needs, leading to greater comfort and reduced accident risks.

- Ergonomic Solutions: Forklift designs increasingly consider ergonomic aspects of work, such as comfortable seats, easily accessible control panels, and support systems for lifting loads.

You can find more information about new technologies in forklifts HERE.

How Forklifts Transformed Logistics

The introduction of forklifts into daily use in warehouses, distribution centers, and construction sites revolutionized the logistics industry. These versatile vehicles have dramatically changed how companies store, handle, and transport goods, bringing far-reaching improvements in efficiency, safety, and scalability of logistics operations.

Improved Efficiency and Throughput

Forklifts have significantly accelerated loading and unloading processes, enabling the rapid movement of large quantities of materials in a short time. This has substantially increased the throughput of warehouses and transport terminals, speeding up supply chains and reducing wait times for goods.

Enhanced Workplace Safety

Forklifts have greatly improved safety in workplaces. Moving heavy and cumbersome loads manually was not only inefficient but also posed a high risk of accidents and injuries. Forklifts have significantly reduced the number of accidents related to handling heavy loads.

Optimization of Warehouse Space

With the ability to lift loads, forklifts have allowed companies to better utilize vertical warehouse space. Storing goods on high racks became possible, greatly increasing warehouse capacity without the need to physically expand the area.

Impact on Supply Chains

Forklifts have contributed to transforming supply chains, making them more flexible and resilient to change. The efficiency with which goods can now be handled allows for faster responses to changing market demands, which is critical in today’s fast-paced economy.

Hangcha – a Leader in Forklift Manufacturing

Currently recognized as the world’s largest forklift manufacturer, Hangcha has revolutionized the material handling equipment market over nearly 70 years of operation. Producing almost 400,000 forklifts annually is a testament to the brand’s unmatched operational scale and innovation.

Hangcha is now synonymous with progress in the forklift industry, particularly in electric forklifts. The company has become a leader in promoting sustainability and eco-friendly solutions in transport and logistics. Hangcha’s presence in the forklift market is of immense significance to the entire industry. Through its continuous pursuit of innovation, the company helps shape the future of the logistics sector by offering products that combine advanced technology, efficiency, and an environmentally conscious approach. Hangcha not only delivers equipment that meets current market needs but also inspires other companies to follow the path of innovation and sustainable development.

If you want to learn more about the history of Hangcha forklifts, visit our previous article, which you can find HERE.

BIURO: +48 617 48 06

BIURO: +48 617 48 06 SERWIS +48 616 91 21

SERWIS +48 616 91 21